Ievads

Optisko instrumentu jomā precizitāte un uzticamība ir ārkārtīgi svarīgas. Šeit noder 8 mm slīdņa lineārie soļu motori. Kompakti, bet jaudīgi, šie motori piedāvā plašu pielietojumu un priekšrocību klāstu, padarot tos neaizstājamus optikas jomā. Neatkarīgi no tā, vai esat pieredzējis inženieris vai optikas entuziasts, izpratne par šo motoru darbību un to priekšrocībām var sniegt jums ievērojamas priekšrocības jūsu projektos.

Kas ir 8 mm slīdņa lineārie soļu motori?

Definīcija un pamatfunkcionalitāte

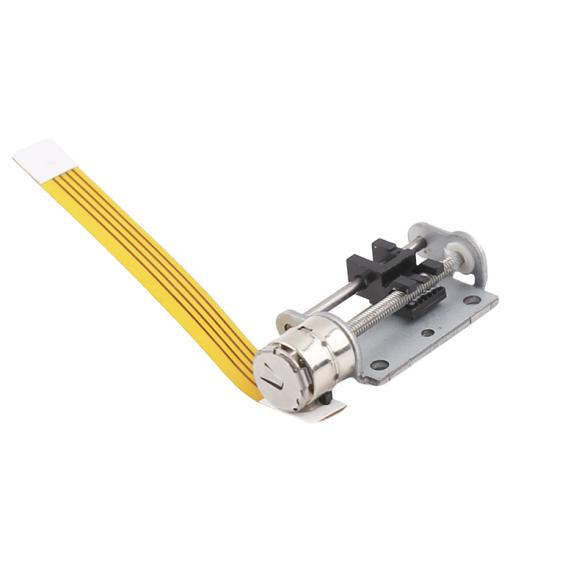

Pēc būtības 8 mm slīdņa lineārais soļu motors ir elektromotora veids, kas pārveido digitālos impulsus precīzā lineārā kustībā. Atšķirībā no tradicionālajiem rotācijas motoriem, soļu motori pārvietojas ar atsevišķiem soļiem, nodrošinot augstu precizitātes līmeni. “8 mm” attiecas uz motora diametru, kas norāda uz tā kompakto izmēru. Šis kompaktums ir ļoti svarīgs lietojumos, kur ir ierobežota vieta.

Galvenās sastāvdaļas un dizains

8 mm slīdņa lineārā soļu motora konstrukcija parasti ietver rotoru, statoru un virkni tinumu. Rotors, kas ir piestiprināts pie kustīgās daļas, pārvietojas ar nelieliem soļiem vai intervāliem ar katru impulsu, kas saņemts no regulatora. Šo kustību vada stators, kurā atrodas spoles un kas nodrošina nepieciešamo magnētisko lauku. Šo motoru precizitāte lielā mērā ir saistīta ar precīzi noregulētu mijiedarbību starp šīm sastāvdaļām.

Soļu motoru loma optiskajos instrumentos

Optisko instrumentu pārskats

Optiskos instrumentus izmanto, lai novērotu un mērītu gaismu un citus elektromagnētiskā starojuma veidus. Šie instrumenti ietver mikroskopus, teleskopus un spektrometrus, un katram no tiem ir nepieciešama precīza dažādu komponentu kontrole, lai tie darbotos pareizi. Šo instrumentu precizitāte var ietekmēt gan novērojumu, gan mērījumu kvalitāti.

Precizitātes un kontroles nozīme

Optiskajos instrumentos pat vismazākā novirze var izraisīt ievērojamas kļūdas. Soļu motori nodrošina precizitāti, kas nepieciešama, lai ar ārkārtīgu precizitāti pielāgotu lēcas, spoguļus un citus optiskos komponentus. Izmantojot soļu motorus, inženieri nodrošina, ka optiskie instrumenti sniedz uzticamus un konsekventus rezultātus.

8 mm slīdošo lineāro soļu motoru pielietojumi

Mikroskopi

Mikroskopos fokusēšanas mehānisma vadībai tiek izmantoti 8 mm slīdņa lineārie soļu motori. Spēja veikt sīkas korekcijas nodrošina, ka paraugi ir perfektā fokusā, kas ir ļoti svarīgi augstas izšķirtspējas attēlveidošanai. Šie motori arī palīdz precīzi pārvietot platformu, lai precīzi novietotu paraugus.

Teleskopi

Teleskopiem soļu motori palīdz pielāgot teleskopa optikas pozīciju. Tas ir īpaši svarīgi teleskopa izlīdzināšanai ar debess objektiem. 8 mm slīdņa motori nodrošina nepieciešamo precizitāti, lai veiktu smalkas korekcijas, kas uzlabo novērojumu precizitāti.

Spektrometri

Spektrometri izmanto 8 mm slīdošos lineāros soļu motorus, lai kontrolētu difrakcijas režģu vai prizmu kustību. Precīza šo komponentu kustība ir būtiska, lai atdalītu gaismu tās komponentu viļņu garumos, ļaujot veikt detalizētu spektrālo analīzi.

8 mm slīdošo lineāro soļu motoru izmantošanas priekšrocības

Uzlabota precizitāte un pareizība

Viena no 8 mm slīdošo lineāro soļu motoru galvenajām priekšrocībām ir to spēja nodrošināt precīzu kustības kontroli. Katrs solis ir nemainīgs, un izšķirtspēja var būt ļoti augsta, kas ļauj precīzi pozicionēt optiskos elementus.

Kompakts izmērs un telpas efektivitāte

Ņemot vērā to mazo izmēru, 8 mm slīdņa lineārie soļu motori ir ideāli piemēroti lietojumiem ar ierobežotu vietu. To kompaktais dizains ļauj tos integrēt mazās optiskās ierīcēs, neapdraudot veiktspēju.

Izturība un uzticamība

Soļu motori ir pazīstami ar savu izturību. Tie var darboties ilgstoši bez ievērojama nodiluma. Šī uzticamība ir ļoti svarīga optiskajos instrumentos, kur nepieciešama nemainīga veiktspēja laika gaitā.

Izmaksu efektivitāte

Salīdzinot ar cita veida motoriem, 8 mm slīdņa lineārie soļu motori ir salīdzinoši rentabli. To efektivitāte un ilgais kalpošanas laiks padara tos par rentablu izvēli precīziem optisko instrumentu pielietojumiem.

8 mm slīdošo lineāro soļu motoru salīdzinājums ar citiem tipiem

salīdzinājumā ar līdzstrāvas motoriem

Līdzstrāvas motori nodrošina vienmērīgu un nepārtrauktu kustību, taču tiem trūkst precīzas vadības, ko nodrošina soļu motori. Optiskos pielietojumos, kur precizitāte ir kritiski svarīga, soļu motori ir labāka izvēle.

salīdzinājumā ar servomotoriem

Servo motori nodrošina augstu precizitāti un vadību, taču tie bieži vien ir lielāki un dārgāki nekā soļu motori. Lietojumiem, kuros vietas un izmaksu ziņā ir ierobežojumi, piemērotāka izvēle ir 8 mm slīdņa lineārie soļu motori.

Nākotnes tendences un inovācijas

Tehnoloģiskie sasniegumi

Tehnoloģijām attīstoties, 8 mm slīdošo lineāro soļu motoru iespējas, visticamāk, uzlabosies. Inovācijas materiālos un ražošanas tehnikās varētu uzlabot to precizitāti, efektivitāti un izturību.

Jaunas lietojumprogrammas

8 mm slīdošo lineāro soļu motoru izmantošana paplašinās ārpus tradicionālajiem optiskajiem instrumentiem. Parādās jauni pielietojumi tādās jomās kā biomedicīnas ierīces un augsto tehnoloģiju instrumenti, kas demonstrē šo motoru daudzpusību un potenciālu.

8 mm slīdņveida lineārie soļu motori ir ieņēmuši savu nišu optisko instrumentu jomā, piedāvājot nepārspējamu precizitāti, kompaktumu un uzticamību. To pielietojums mikroskopos, teleskopos un spektrometros uzsver to nozīmi precīzu un konsekventu rezultātu nodrošināšanā. Tehnoloģijām turpinot attīstīties, šiem motoriem ir arvien nozīmīgāka loma optisko instrumentu attīstībā. Neatkarīgi no tā, vai izstrādājat jaunas optiskās ierīces vai uzlabojat esošās, 8 mm slīdņveida lineāro soļu motoru priekšrocību izpratne un izmantošana var mainīt spēles noteikumus.

Publicēšanas laiks: 2024. gada 16. jūlijs